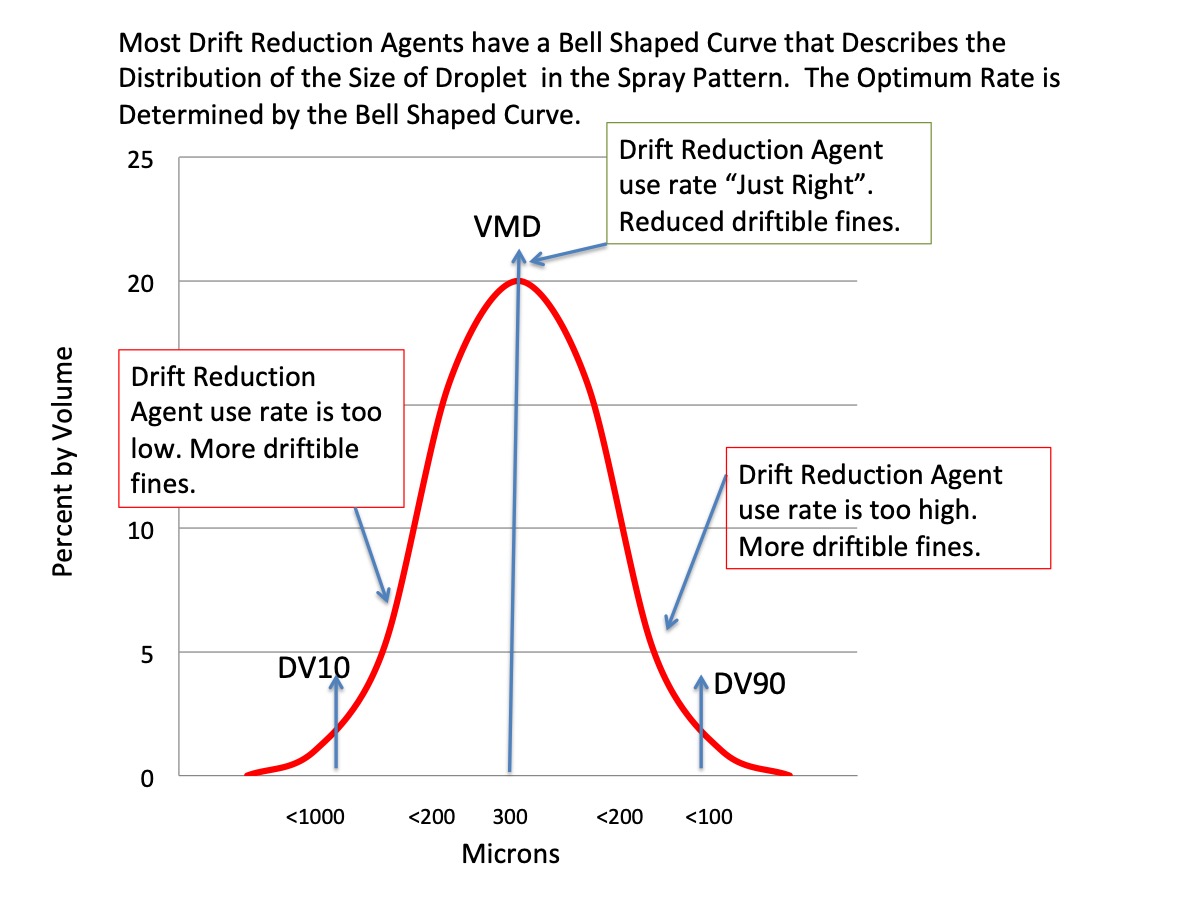

Graph Explained

Drift reduction adjuvants want to increase droplet size but not increase surface tension. This usually means increasing the tensile strength of the water carrier of the spray solution. Almost all drift reduction agents work this way. The surface tension is not altered so your surfactant continues to work. However, the water carrier holds together longer as it exits the spray nozzle thus making a bigger drops. However, if the water holds together too tightly, when it does manage to break up into droplets, it breaks up into smaller, called “driftable fines”.

Below a bell shaped curve shows the size of water droplets in microns as affected by the use rate of Drift-fiant on a spray volume basis. In other words there is an optimum “use rate”, too low of a “use rate”, no effect or limited effect, too high of a “use rate” too great of an effect meaning--the spray droplet will get small again. For most ground rigs that “use rate” is about 24oz per 100 gallons of spray solution.

A lot of talk these days about spray drift below are some explanations that might be helpful understanding what some people are saying.

Drift-Faint works by increasing the tensile strength of the water. This way, as the spray mix comes out to the spray nozzles it stretches more before it breaks into droplets making bigger droplets. However, if the pressure is high and the “use rate of Drift-fiant too high the spray will stretch too long and then when the spray stream breaks it can break into smaller droplets. Shear, pressure and spray volume along with “use rate” dictate the shape of a bell shaped curve. Where this bell shaped curve moves in relationship to to shear, pressure and volume dictate the “use rate” of Drift-Faint and other drift reduction products.

In other words with most drift reduction agents including Drift-fiant the adage a little is good then more is better is usually not true.

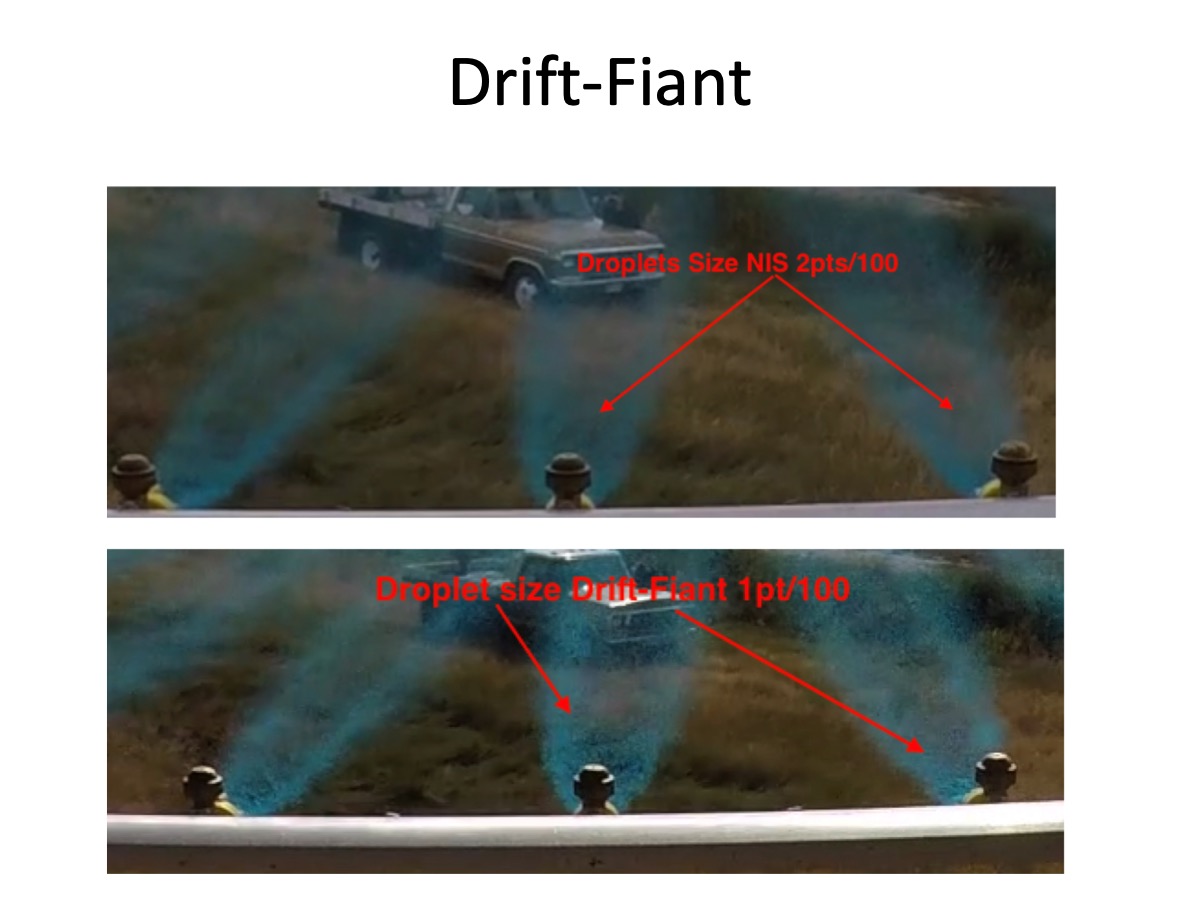

Nice graph, but the picture of bigger droplets coming out of a spray nozzle during and aerial application of a 1pt/100 application is better.

Recently the Canadian Aerial Applicators had a “Fly In” where they tested different drift reduction agents. Drift-fiant was number 1. the graph below is a bar graph that show real data that make up a “bell shaped” curve. The taller the bars in the middle and the shorter the bars on both ends the better the efficacy. The shorter the bars on the left the less drift potential. The shorter the bars on the right the less loss from droplet “bounce off”.

Another way of looking at it is percentage of the application that was lost by either the spray droplets being too small and drifting away or being too big and bouncing off the target plant. In this example Drift-fiant less than half the loss of the other drift reduction agents. The reason for this is that Drift-fiant was designed to not only reduce driftable fines but also reduce the number of very large spray droplets.

Spray Droplet size with Drift-fiant on a small utility sprayer.

Reduction of small droplets and large droplets is defined by “Relative Span” which is a measure used to define the percentage of the spray droplets that are in a optimal size for efficacy while decreasing the drift potential. a good number for Relative Span is around 1. In this case Drift-fiant’s relative span was 0.91. But the most important fact is that you get more of the active ingredient on target.

Another shot of how Drift-fiant affects the spray pattern this time a spraying on a 4 wheeler.